In the words of Eric Burdon, "We gotta get out of this place if its the last thing we ever do." The marina where Fir sits has been in some state of legal trouble for years. San Joaquin County, California has cited the marina operator for a variety of infractions. Eventually, this led to the lender foreclosing on the property. This plus a host of lesser disputes and accusations have been advancing slowly through the local courts.

Navigation (Part 1)

General

We decided to build two independent navigation systems. One system will be based around chartplotters from a major marine electronic manufacturer (final selection not made). The second, will be a PC based solution. Obviously, having two systems creates redundancy. However, two systems based on very different platforms will decrease the chances of a single problem taking out both.

Navigation Computer

Our navigation computer is housed in a generic 8U rack cabinet. Below the computer is the Ubiquiti ethernet switch. The Rose Point interface is to the right.

We completed the physical set up of PC systems. Snapping components into our generic computer cabinet was quick and easy. Loading Windows 10 created a "missing file" error message which was a PITA. We spent 4-5 hours googling the error message and trying to resolve the problem on board. When we got sick of this, we pulled it out and took it to a local computer repair shop. It turned out that the stick provided by Microsoft was bad so we were never going to solve the problem on board. This twist of fate turned out to be a benefit when the computer shop quickly loaded all our software which would have taken days on board through our cellular connection.

The homemade computer is lightning fast and the display is gorgeous. We are very happy with our selections so far.

In choosing an internet connection, we borrowed heavily from Panbo's recent articles before purchasing a Netgear LB-1120 4G cellular modem ($88), and MIMO antenna ($27). When combined with our Shakespeare cellular amplifier (more to come on this), cellular coverage is excellent.

The bridge between our computer and internet sources is a Ubiquiti Edge Router ($184 ). This is a "managed" router and switch that decides how to move data across our internal network. This unit can be configured to choose between two internet sources. In our case, the unit will use a WIFI connection if possible. Should no reliable WIFI be available the unit will make use of the signal from the Netgear cellular modem. Setup for the Ubiquiti unit is a challenge. Fortunately, this only has to be done once. I used Ubiquiti products on a previous project and was so impressed that I invested in the stock. Go Ubiquiti Networks Inc.,NASDAQ: UBNT

Charting Software

There are several good PC based navigation packages. We selected Coastal Explorer from Rose Point ($379 for download version). Rose Point is a Washington State company started by one of the founders of Microsoft

In making our decision, we read the sales materials, studied a number of YouTube videos, and spoke to sales reps at boat shows. But, the most compelling endorsement came from the Adventures of Tanglewood.

Coastal Explorer offers excellent planning facilities. One can easily flip between raster and vector charts and charts from different sources. So, we can plan a route using basic vector charts. We can then study the route using raster charts and charts from other sources. The idea is that we will build our routes based on all the available information. This PC based system will interface with our autopilot.

A large part of our decision was driven by Rose Point's Nemo interface ($699). Nemo is a device that enables communication between the NMEA2000 and NMEA0183 marine devices, and a computer. There are a number of ways to accomplish this. Nemo pulls all the information into a single box, and fully complies with NMEA standards making the system more stable than many other interfaces.

Nemo will let us select (or ignore) devices connected to the system, which is critical. On the one hand, we want an integrated system and the ability to incorporate new technology. On the other hand, we want to ensure that there is a firewall between our central navigation system and recreational devices. Nemo will prevent other devices from interfering with our navigation system.

We can also set priorities. We have multiple GPS sources. Nemo allows us to select the order in which the GPS are used. We will program Nemo to first use our reference quality Lars Thrane GPS system on its NMEA 0183 wiring and then the Furuno LT-1000 if the Lars Thrane fails.

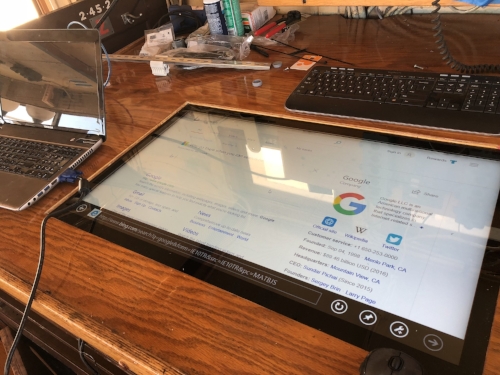

The display for our PC based navigation system is flush mounted in the original chart table. This is a touch screen system. We do have a backup keyboard and mouse in the top drawer (visible in the lower left portion of the photograph). Since the screen is flush mounted, we can easily use the table for traditional, paper charts. Note that the glare is a problem with the camera.

We also loaded PredictWind onto the navigation computer. PredictWind is a subscription service. There is a free version that shows wind and wave predictions in increments of 50KM. A paid subscription service offers weather models in 1KM increments. This allows us to select between PredictWind's proprietary weather models as well as the most popular publicly available models. The system will download GRIB files (standard weather files)and push them into our chartplotters and navigation computer.

PredictWind also offers route planning assistance. We enter the intended route that we developed using Coastal Explorer. PredictWind then calculates the best date and time for our departure. We can also use PredictWind to adjust our route for the most comfortable course considering wave predictions.

A sample screen with general wind data. More detailed information is by subscription.

Wind and wave data in table form.

Memorial Day Weekend -- Water Tanks, Computers, and Sleds

Another coat of PS700 to the port freeboard. Primer on the aft mast. Note the new decal on the bow.

Painting

Painting Fir is a combination of practicality and pride. She would be easier to paint in a shipyard. Our PPG paints are very forgiving which means we can often pull off painting when the weather and lack of supplies prevents other work. The paint is protecting her from the elements which is necessary for trips to harsher environments. In addition, painting forces careful inspection of every surface which allows us to ensure we know every issue with the hull.

A fresh coat of paint prevents us from looking like a derelict vessel. California and San Joaquin County in particular have issues with derelict boats. A San Joaquin County video seems to define a derelict boats as one that "needs love." As a matter of pride, we want to roll into the Bay looking good -- and loved.

Water Tanks

The last coat of Amerlock 2/400 goes into the aft tanks. Ready to close.

Getting the water tanks right has been a major pursuit. We need clean, potable water. Equally important, Fir's six belly tanks cover a large portion of the underwater hull. They essentially provide a double hull structure. There is an old saying that steel boats rot from the inside out. Protecting the hull and developing a good seal is a significant safety issue.

Furthermore, the water tanks are also our ballast. The tanks will be drained for a short trip from her current mooring to the Stockton shipping channel. Once in the channel, we need to take on water to provide much needed ballast.

Chris installs new gaskets for the tanks and cleans around the seals.

Computers and electronics

We plan to have two computers: 1) a navigation computer and 2) a ship's computer.

This trip we started to get the computers up and running. This includes getting our WIFI and Cellular internet connections online. Building the computers from components is as simple as snapping a few cards into place. Its been 15 years since I last did this. 15 years later my biggest problem is I can no longer easily read the tiny labels on the wires. Luckily, Chris is a bit younger and was able to get the wires into the right plugs.

Our next blog will have a complete description of our system and our plan to integrate marine equipment with the PC. We also hope to select and load our PC based navigation. This will be one of our two navigation systems.

Testing the electronic chart table using a laptop. We are keeping the original chart table but we are flush mounting a 30 inch monitor to display electronic charts.

Sleds

Our new equipment will be grouped by function and mounted on sleds for a single source of control. We worked on three sleds this trip: 1) the fresh water sled that takes care of our water making and domestic water distribution, 2) the HVAC sled that houses our boiler, hydronic heat distribution, domestic hot water production and rack of chillers for cooling and 3) the sled for new generators. We will soon be making our final decisions on these systems.

The beginnings of our water sled where water filters, water maker, and pumps will be mounted.

Getting our home built computer up and running. Loading Windows etc.

Painting the aft mast relates to our electronics in that this is where we will install the last of our Shakespeare antennas and remainder of our McDermott navigation lights.

Chris pressure washes the aft mast in preparation for priming.

This sled added to the engine room will house the boiler for domestic hot water and heating and the chiller block.

An advantage of the sled is that it gives us fewer connection points to Fir's current systems. Connecting to Fir's existing systems can be challenging. The braided wiring can be tough to strip. Pipes can be frozen. Splicing into existing pipes can lead to breaking parts which leads to endless searching for a part on the boat and ultimately ending with an hour trip to Fergusons. The sleds limit the number of connections to existing systems. For example, the water sled will have power, water in, and water out. All the plumbing and wiring within the sled are new and matched with the other new components. Connecting these components is relatively quick and predictable. The sled allows us to deal with a few key splices and move on with the install ion a predictable fashion.

Bathymetry (Depth Soundings)

Mother's Day Makes for a Short Trip

I had to get back to the east coast to see my mother for Mother's Day so this was a quick 3 day trip.

Paint

During the last trip we applied the second coat of Amerlock 2/400 to the starboard side. We are using the Amerlock as a primer. This trip we followed with the first coat of PSX700 below the bumper. Since Fir has nearly no water or fuel on board, we are able to reach what will be underwater when she is fully provisioned.

After some experimentation with barges and painting methods, we settled on a makeshift float, pictured below. It's narrow profile kept the wind effect at a minimum while giving us access to low points on the hull. Because the material is relatively soft, we could get very close without scratching our previous work.

Eric and Chris apply the PSX700 top coat to the lower fantail with brush and rollers.

The first coat of PSX700 on the starboard side.

Access

Access to the boat has been problematic. We have been using a step ladder from the floating dock to the buoy deck. The combination of a ladder on a dock that hasn't been maintained makes moving heavier supplies punishing to say the least.

Fir originally had a 01 deck door. At some point, a previous owner welded the door shut. We need this door to load the provisions that we require -- not the least of which is motor oil whose fill station is just inside the door.

Joe and Chris by the new entrance. The door is 7/8" of steel weighing in at about 800lbs. Joe lowered it for the first time using a chain fall.

A secondary issue is the vegetation (hyacinth) that has grown between the shore and the floating dock. Since the marina is no longer maintained where Fir is moored, the hyacinth has become so thick that it has managed to push Fir from shore. In addition to the excess vegetation, Fir cannot be accessed on the port side, which happens to be where the door is located.

Joe and Chris used a small boat to break up the mass of plants, dragging clumps into the channel by anchor. With this work done, we ought to be able to move a barge to the door for loading.

Potable Water

We have drained all of Fir's 6 potable water storage tanks, (with the exception of water in the day tank for cleaning). This has been important for three reasons:

We need to insure that the boat is not leaking. Fir's water tanks are built into the hull. The bottom and sides of each water tank is the hull. When the tanks are filled, the hydrostatic pressure inside and outside of the tank is nearly equal so it is impossible to tell if the hull portion of the tank is leaking. Emptying and drying out the tanks is a critical step in checking the condition of the hull. This area had not been tested by our surveyor because the tanks were full during inspection.

Second, we want to clean the tanks we rely on for potable water. See the previous post for our work on the water tanks. This trip we decided that the tanks required more time to dry out.

We added a new bronze valve from the outside water supply on the aft seachest. This line will feed our potable water filters and watermaker.

Third, Fir needs to be high in the water when we take her from her current mooring to the main shipping channel, about 1,000 yards away. The Fir draws 11.5 feet when properly provisioned. She is probably drawing 9 feet today because her tanks are empty. We have concerns that the area where the channel meets the shipping lane may be too narrow to accommodate Fir.

While we want Fir high in the water as she leaves her current mooring, potable water is a major source of ballast. We need to fill the potable water tanks as soon as we make it to the shipping lane. Our water source will be an existing valve off of the aft sea chest. Joe opened the old valve (leaving it in place) and installed a new bronze valve from Groco.

Joe installed the rack that will hold our new potable water system. The red pumps below the rack are the #2 fire pumps. The blue pump connected with PVC pipe is a temporary pump installed by the previous owner. The temporary pump and PVC pipe will be replaced with marine equipment mounted to the rack. The rack is fairly high in the air so that the strainers for the fire pumps can be maintained.

April 25 - April 30, 2018

Chis Willson emerges in active respiration gear after spraying the tanks. Joe on deck in case Chris passes out in the tank.

We started cleaning the water tanks with CLR and a 4,200 psi pressure washer fitted with a turbo nozzle. The results were fairly disappointing. We then turned to the Duraprep 88 from PPG. The Duraprep was much more effective in removing rust stains. We then spot painted bare areas in the tank with black Amerlock 2/400 (mostly joints and a number of rivet heads) and let it cure for several days. Chris wore a full active air respirator and hazmat suit to spray the entire tank white with Amerlock 2/400.

First of Spring

The weather is becoming more predictable. Not predictable enough to order our generators (which have to be craned through the roof of the boat) or complete the mast wiring. However, we were able to make progress on painting, porthole welding, and repairing scuppers.

Paint

We are using Amerlock 400/2 as a primer and PSX 700 as the top coat. Both are industrial paints from PPG. It has taken several applications to get accustomed to the paint, and now it's working very well. The Amerlock is watertight with three applications by roller. It cures above 30 degrees, is rain safe in 6 hours (with northern California winds), and hard as steel in 24 hours. The paint takes on a high sheen that is good as a final coat on most work surfaces.

The PSX 700 also cures above 30 degrees, but is ready to recoat in 4 hours. The coating is high gloss, and can be patched without leaving a trace (critical since we cannot get the entire boat prepped at one time with our limited crew). PSX 700 can be recoated without sanding which is a major advantage, and the coverage is excellent. It takes about 6 gallons to coat one side of the boat with Amerlock, and a little more than 2 gallons to cover the same area with PSX 700.

The prep has been minimal. We have numerous rust spots about the size of a quarter, and about a dozen rust problems where two plates meet. Paint used by the previous owner simply washed off, and below this coat of cheap paint was the last coat applied by the Coast Guard. It is tough. No need to scrap or chip this base.

Fir as she sat when we found her in the winter of 2016.

A few months later in the Spring of 2017. At this point we are color testing the white on the A Frame and the red and blue on the stack.

Late fall 2017. Note the tenders have been removed from the aft deck. Solar panels added. A first coat of PSX700 has been applied to the superstructure. A final coat of PSX700 red and blue has been applied to the stack.

Early spring 2018. Amerlock primer is applied to the freeboard. Note that the "phone booth" above the wheelhouse has been removed.

Two coats of Amerlock primer later, we applied the blue PSX700 below the bumper.

The first coats of PSC700 white, red, and blue are applied to the forward freeboard. Amerlock black applied to the anchor and anchor box.

Portholes

For whatever reason, the starboard side of the boat took the brunt of the weather over the last couple of years. This trip, Joe completed welding the last of the portholes. We painted the hull under the portholes with Amerlock to create a barrier. And, when Joe re-installed the portholes, he coated the internal lip with PPG chalk.

During the porthole restoration process, we cut 43 brass slotted screws. They have to be custom made at a cost of $13 each -- ouch.

Water Tanks

We took another pass at the aft water tanks. The water tanks are tough because they dry slowly due to poor air circulation. We pressure washed the tank on the last trip. Then we spot blasted in the beginning of this trip. Once dry, Amerlock 400/2 was applied to bare metal spots. Amerlock is rated for underwater service but the coating has to be thick. We coated the bare spots with black Amerlock. We will come back with a more general coating in white.

Wardroom

The old wardroom ceiling had been covered with a variety of paints. This was not a big deal because the last restoration included the installation of a drop ceiling. We want to go back to the original tin ceiling. Between rain storms, we used a cheap needle gun from Harbor Freight to remove the old paint.